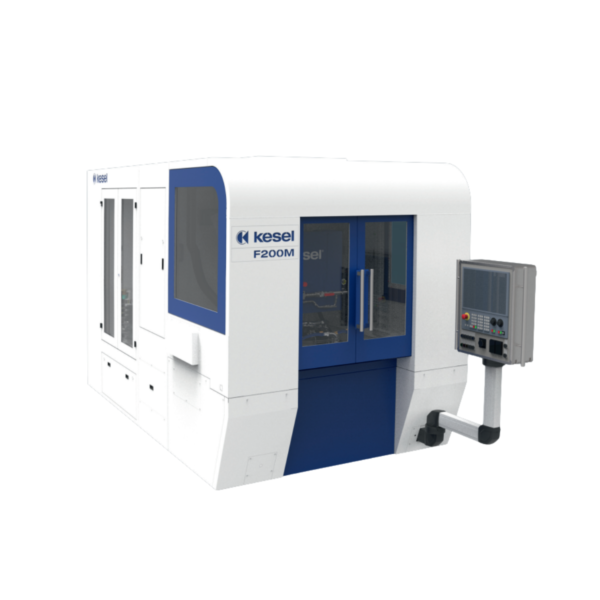

Georg Kesel – Coss-Serrated Flange Milling Machine – F200M

The Kesel Coss-Serrated Flange Milling Machine F200M is built upon years of experience in the linear toothing and cross serration areas of machine tool manufacture and operation. The F200M, Kesel’s brand-new model, has been specifically designed and engineered for world-leading creation of cross serration in flanges and similar products.

Delivering high-volume productivity and ultimate milling quality the F200M is able to meet ISO 8667 and 12667 standards with ease whilst offering flexibility for projects with custom toothing designs.

As with many other machining applications, with cross serration, robust and precise work holding is essential. The F200M has been engineered with a multi-level clamping system that not only ensures your parts are accurately clamped but also means that you can utilise the full speed and performance of the F2-SK milling head. The F200M. Exceed all X-pectations.

Technical Specification

| Milling Head | Type | F2-SK |

| Power | 43 kW S6 40 % | |

| RPM | Max. 315 U/min | |

| Max. Tool width | 200 mm | |

| Milling Arbor | SK 50 | |

| Travel Ranges | X-axis (horizontal / table) | ± 15 mm |

| Y-axis (vertical / depth) | 230 mm | |

| Z-axis (traverse / infeed) | 370 mm | |

| B-axis (clamping system) | 0 – 70 ° | |

| Control | Siemens SINUMERIK 840D sl | |

| Clamping System | Maßgeschneiderter Flanschspanneinheit auf einem Drehtisch | |

| Dimensions and Weight | Machine weight | 16.000 kg |

| Installation dimensions (L x W x H) | 5.200 x 2.900 x 2.700 mm |

Key Features

- A dedicated machine for cross-serration of companion, yoke and shaft flanges.

- Quality and precision that exceeds ISO 8667 and 12667 requirements.

- Fully automated loading options for ultimate ROI.

The Kesel F200M Cross-Serrated Flange Milling Machine

The Kesel F200M is built upon years of experience in the linear toothing and cross serration areas of machine tool manufacture and operation. The F200M, Kesel’s brand-new model, has been specifically designed and engineered for world-leading creation of cross serration in flanges and similar products.

Delivering high-volume productivity and ultimate milling quality the F200M is able to meet ISO 8667 and 12667 standards with ease whilst offering flexibility for projects with custom toothing designs. As with many other machining applications, with cross serration, robust and precise work holding is essential. The F200M has been engineered with a multi-level clamping system that not only ensures your parts are accurately clamped but also means that you can utilise the full speed and performance of the F2-SK milling head.

Key Industries

- Aerospace

- Automotive

- Defense

- Die & Mould

- Education & Academics

- Electronics

- Machinery & Manufacturing

- Medical

- Mining & Minerals

- Oil & Gas

- Semiconductor, Solar & Electronics

- Shipbuilding

More Products

Georg Kesel GmbH & Co. KG is an internationally recognized manufacturer of machine tools for linear tooth profile milling. These…