FlowGen – Wind Turbine Systems

Access to energy, particularly cleaner energy, is fundamental to human progress. The majority of the world’s energy poor lives in Asia, Pacific and Africa. Many with access to power use diesel generators!

Access to energy, particularly cleaner energy, is fundamental to human progress. The majority of the world’s energy poor lives in Asia, Pacific and Africa. Many with access to power use diesel generators!

What is the solution? – cost-effective smart microgrid embracing wind, solar and battery.

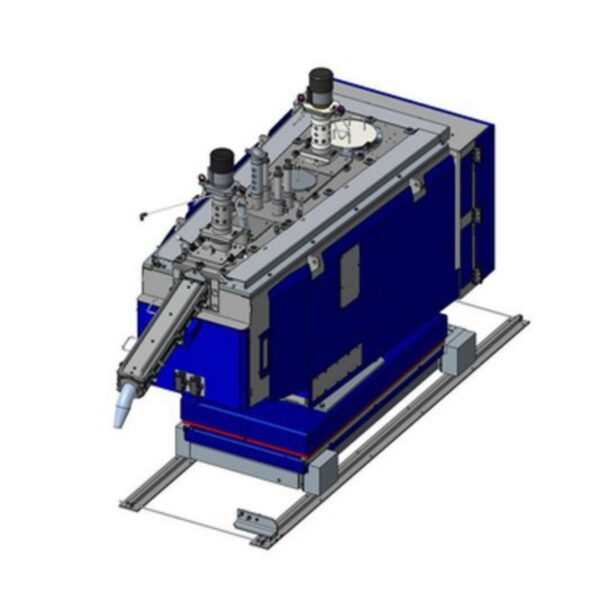

FlowGen mobile energy solutions come ready to use in a 40ft-container setup, which includes the following components and features:

- 4 wind turbines with a rated power of 10kW each

- Powerful 30kW inverter per turbine set for small-grid installations – either as independent island system, but as well operational together with an existing island grid (e.g. from a diesel gen-set or other AC- or DC-power sources). Beyond the inverter always allows grid-parallel operation if desired.

- A 600V DC-Bus from the inverter is accessible for DC-coupling of battery-storages of different sizes or can be coupled to DC-fed speed inverters for water-pumps, compressors or other variable speed applications. By this a maximum efficiency is provided as ac/dc/ac – losses can be avoided

- The set further includes a ready to mount photovoltaic generator of scalable size – e.g. 40kW as a standard. The pv generator is dc-coupled and controlled by the wind turbine inverter for maximum energy efficiency.

- In cases where a high flexibility in power production is desired FlowGen can provide gen-sets powered by diesel or natural gas for backup in scalable sizes.

- The automation and control setup will always balance energy flows in the best possible way and harvest at maximum efficiency your natural resources.

- Besides local information via gauges, screens and a service-personnel app for remote control, the user may rely on the centralized services of the FlowGen data center, that gathers all additional information of the power system and allows predictive maintenance, hurricane protection by safe shut-down of the turbines and many other features which allows to permanently optimize the energy output of the installation.

The sets can be moved in standard containers to any location on the globe and set up for operation within short time to provide environmentally friendly produced energy at no grid cost wherever it is needed.