Sandon Global – Anilox Rollers & Sleeves – Laser Engraved Ceramic Coated – Narrow Web

The narrow-web category provides a unique set of challenges and an endless range of finishing, coating and decoration options which drives our appetite for product development. More recently embracing the industry trends towards hybrid flexo-digital presses and the adoption of LED curing technology.

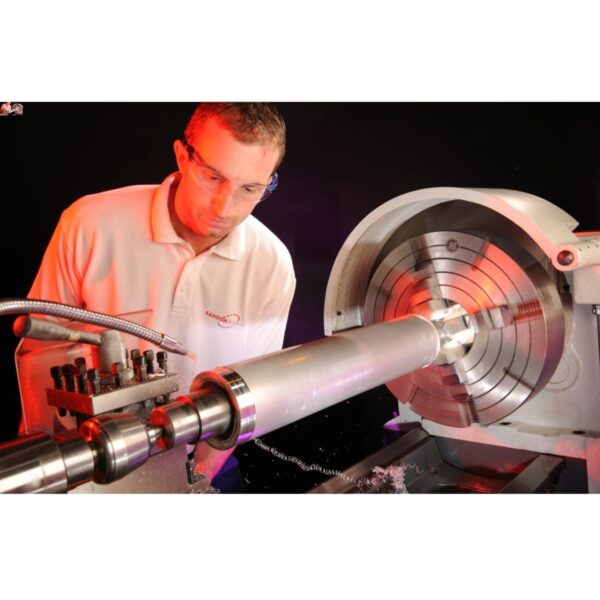

We take great pride in the performance and engraving consistency produced by our time-served engineers, laser operators and finishers.

Key Features

- Vibrant colors

- Reduce anilox inventories

Available Models

Fluid UV Combination Engraving for Solid and Tone Work

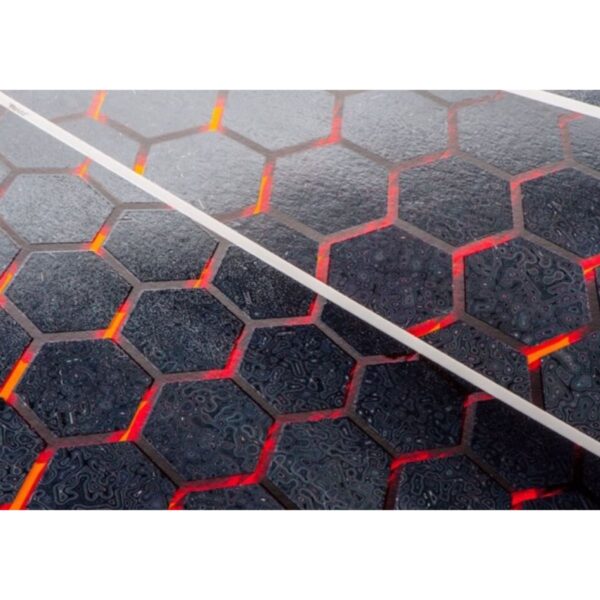

Fluid HEX 60º Anilox Engraving

XPRO Anilox Engraving

High Opacity White (HOW) Anilox Engraving

Key Industries

- Machinery & Manufacturing

More Products

Sandon Global is a leading anilox roll supplier based in the United Kingdom. Sandon Global manufactures and refurbishes anilox rolls,…