Georg Kesel – Band Straightening Machine – BR 100s

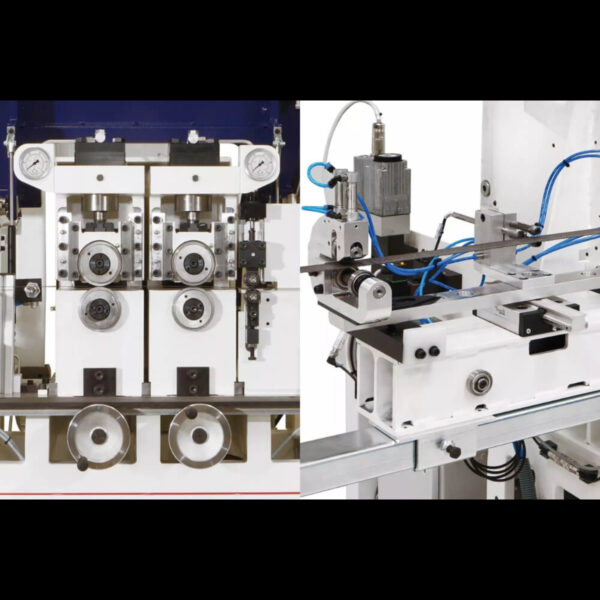

Improve quality, speed up manufacturing and add additional value to your saw products with the BR 100s automatic straightening machine. Designed for ease of operation, the BR 100s is a ‘Plug and Play’ machine that will either straighten-out unwanted camber or create a defined camber at the touch of a button.

With its intelligent ‘teach-in’ operating system the BR 100s automatically learns the optimal parameters required to process each band material and camber and will self-adjust to maintain perfect results. This gives your machine operators freedom to complete other tasks and also means that unparalleled production volumes can be reached.

With optional titling pay-out and take-up units and integrated slack monitoring, material handling and transportation is seamless. And with the ability to export a digital straightening protocol the BR 100s can also form a valuable part of your QC management system.

Technical Specification

| Bandsaw Data | Bandwidth | 12 – 100 mm |

| Band Thickness | 0.65 – 1.6 mm | |

| Control | S7 300 SoftSPS (IPC) | |

| Precision and Productivity | Accuracy | < 0,5 mm/m |

| Speed | 2 – 40 m/min | |

| Coiling System | Options | Tilting coiling |

| Max. coil diameter | max. 800 mm | |

| Max. coil weight | max. 180 kg | |

| Adjustable Hub | 300 – 700 mm | |

| Coil fixture with four jaws | Centric hand feed | |

| Dimensions and Weight | Installation dimensions (L x W x H) | 12,000 x 2,000 x 2,000 mm (incl. control cabinet and coiling system) |

| Machine weight | approx. 3,300 kg (incl. control cabinet and coiling system) | |

| Options | Tilting coiling stations to ease material handling. Machine can be configured for left or right-hand feed direction. |

Key Features

- The BR 100s not only straightens but can also create defined cambers at the touch of a button.

- The BR 100s integrated teach-in function optimises speed and productivity.

- The unique tilting coiling system ensures rapid coil changeovers.

The Kesel BR-100s Band Straightening Machine | Bandrichtmaschine

Improve quality, speed up manufacturing and add additional value to your saw products with the BR 100s automatic straightening machine. Designed for ease of operation, the BR 100s is a ‘Plug and Play’ machine that will either straighten-out unwanted camber or create a defined camber at the touch of a button. With its intelligent ‘teach-in’ operating system the BR 100s automatically learns the optimal parameters required to process each band material and camber and will self-adjust to maintain perfect results. This gives your machine operators freedom to complete other tasks and also means that unparalleled production volumes can be reached.

With optional titling pay-out and take-up units and integrated slack monitoring, material handling and transportation is seamless. And with the ability to export a digital straightening protocol the BR 100s can also form a valuable part of your QC management system.

Key Industries

- Aerospace

- Automotive

- Defense

- Die & Mould

- Education & Academics

- Electronics

- Machinery & Manufacturing

- Medical

- Mining & Minerals

- Oil & Gas

- Semiconductor, Solar & Electronics

- Shipbuilding

More Products

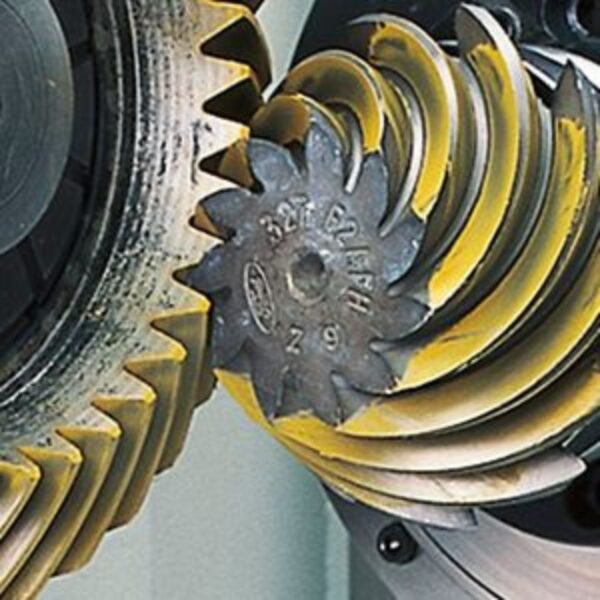

Georg Kesel GmbH & Co. KG is an internationally recognized manufacturer of machine tools for linear tooth profile milling. These…