Georg Kesel – Gear Rack and Profile Milling Machine – R-Series

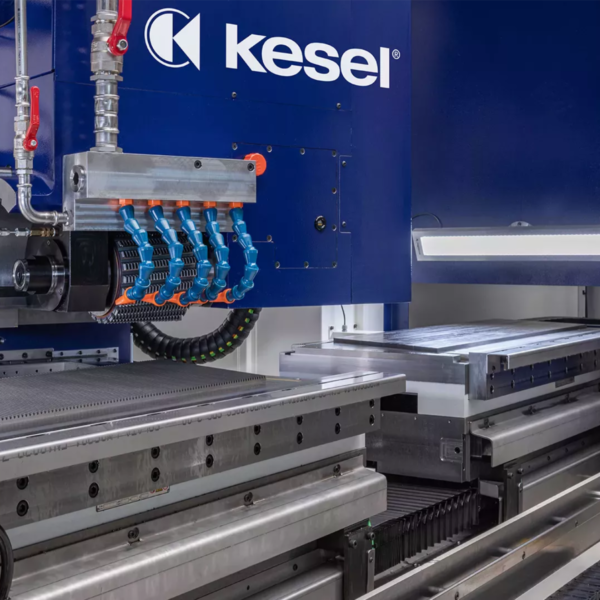

The Gear Rack and Profile Milling Machines of the Kesel R-Series aren’t just updated versions of our previous models, they are completely new rack milling platforms. With a brand new bed and slide construction, a world-first, twin-table system, a completely new milling head and the possibility to fully automate loading and unloading of parts; the R-Series really is a true game changer.

Available in four size variations from the R2500M up to the R5500M and fitted with either our powerful F1-HSK or more compact F2-SK milling head, there is a configuration to fit every application. The R-Series machines are capable of milling up to module 32 on work pieces with a maximum length of 5,500 mm. Built with the latest 840Dsl operating system from Siemens the R-Series is equipped for the challenges of today and tomorrow.

Technical Specification

| Milling Head | Type | F2-SK |

| Power | 43 kW S6 40 % | |

| RPM | Max. 315 rpm | |

| Max. Tool Width | 200 mm | |

| Milling Arbor | SK 50 | |

| Alternate Milling Head | Type | F1-HSK, transmission with high power drive |

| Power | 45kW S6 40% | |

| RPM | max. 450 rpm, infinitely variable | |

| Max. Tool Width | 250 mm | |

| Milling Arbor | HSK-125B | |

| Travel Ranges | X-axis (horizontal / table) | Single table setup from 2,940 mm up to 5.940 mm X2T twin-table system from ± 800 mm up to ± 2,300 mm per table |

| Y-axis (vertical / depth) | 250 mm | |

| Z-axis (traverse / infeed) | 620 mm | |

| B-axis (rotation / helix) | +/- 25° | |

| Control | Siemens SINUMERIK 840D sl | |

| Clamping | Clamping System | Magnetic, hydraulic or hybrid options available |

| Clamping Range | Single table setup from 2,500 up to 5,500 x 400 mm, X2T twin-table system from 2 x 1,250 up to 2 x 2,750 x 400 mm | |

| Dimensions and Weight | Installation dimensions (L x W x H) | R2500M : 8,600 x 4,300 x 2,700mm R3500M: 9,600 x 4,300 x 2,700mm R4500M: 11,200 x 4,300 x 2,700mm R5500M: 13,600 x 4,300 x 2,700mm |

| Machine weight | R2500M ≈ 26 t R3500M ≈ 29 t R4500M ≈ 32 t R5500M ≈ 35 t | |

| Options | X2T twin-table system Controlled B-axis Milling cutter changing device SW3K chip vacuum system – Automated loading and unloading …And much more! |

Key Features

- The brand new F1-HSK milling head packs more power and performance than ever before!

- The X2T twin-table setup will allow you to achieve unbelievable productivity.

- Fully automate your loading and unloading process with our latest robotic cell.

The R Series from Kesel. Rack and Profile Milling Machine.

The machines of the Kesel R-Series aren’t just updated versions of our previous models, they are completely new rack milling platforms. With a brand new bed and slide construction, a world-first, twin-table system, a completely new milling head and the possibility to fully automate loading and unloading of parts; the R-Series really is a true game changer.

Key Industries

- Aerospace

- Automotive

- Defense

- Die & Mould

- Education & Academics

- Electronics

- Machinery & Manufacturing

- Medical

- Mining & Minerals

- Oil & Gas

- Semiconductor, Solar & Electronics

- Shipbuilding

More Products

Georg Kesel GmbH & Co. KG is an internationally recognized manufacturer of machine tools for linear tooth profile milling. These…